Flying

Bench Testing

Assembly was completed in three evenings. When the last

component was screwed in place, I connected up the battery, switched on

the Tx and… disaster

(well, almost)! The main rotors

immediately spun up and I watched in horror as the

Piccolo edged off the workbench with rotor blades

flailing and then fell in a heap of ball joints on the workshop floor.

Well much to my amazement nothing

broke – the ball links simply un-balled themselves.

The main problem was finding the rotor bearings which had

been flung to opposite ends of the workshop.

The cause was interference from a nearby fluorescent lamp. I learnt some useful safety lessons:

- Disengage the main motor pinion before your

first bench test. Do this by simply pushing the rotor head down

firmly, so the silicone sleeve slides up the shaft. Check the

sense of the throttle stick v. the Piccoboard, only then should

you re-engage the pinion.

- Always check your throttle lever is at low

throttle before you switch on

- Always switch the Tx on first!

Setting Up

Before the first flight, take a few minutes to

take stock of things and check your setup:

-

The swashplate must follow the

stick, i.e. forward on the stick and the swashplate tips forward. The

instructions are a bit vague about this, if you just follow your

aerodynamic instincts without taking into account gyroscopic lag,

your swashplate will end up 90 degrees out of phase. Been there,

done that!

- Balance the model fore/aft by holding

the rotor head with the rotors at 90° to the body.

Shifting the battery pack until it balances level.

- To start with place some balsa packing under

the left skid as recommended in the instructions, this makes

takeoffs much easier until you get used to the leftways drift. The

model must in any case fly with a slight right-side tilt to

counteract the sideways thrust of the tail rotor.

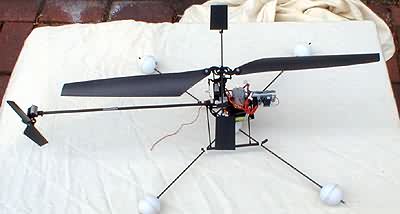

Note trainer gear - carbon rod and

ping balls. Canopy removed for first flights.

Test flights

My living room offered a suitable space about 12 ft * 15

ft with a wooden floor, and I would not suggest anything much smaller

than that. I spent the first "flights" just getting the trims and mixing

right without lifting off. Gradually the model started scuttling around

in ground effect, like a demented crab.

Fly, crash,

re-adjust, fly etc. was the order of the day for

the first several flights. However the model is

remarkably tough, the main rotor just flies apart at the

ball joints. Breakages are generally easily fixed with cyano.

Incredible really given the amount of punishment it's

received.

Gradually my flight times increased and confidence

grew, and I can now fly the model

quite comfortably in the living room including nose in, and slow

360-degree pirouettes in front of me.

Some tips:

-

During take off, get out of ground effect as

quickly as you can. GE extends to about 1 ft clear air below the skids.

-

Once in the air, adjust the trims so you can take your fingers off the

sticks for a second in the hover. If the model is nicely

trimmed hands off, it's a lot easier to handle.

- A little negative

exponential for pitch and roll controls

seems to makes the model smoother to fly.

Your mileage may vary.

- The main shaft has a

silicone tube retainer which can slip

following a hard landing - the shaft

should be checked after a hard landing.

Piccofly Simulator

The Piccofly simulator is a very

effective training aid which I strongly recommend

for rookie chopper pilots (see my review of

the Piccofly sim). With

the sim I was able to practice nose-in and

pirouettes without risking the model.

|