Review: Volz WingMaxx servo

The Volz WingMaxx is a slim wing servo from Volz of Germany. It combines speed and torque in a very slim (10mm) package.

Photo shows WingMaxx with Hitec HS80 for comparison

Specs

The manufacturer's figures are as follows.

| Size | 49x30x10 mm |

| Bearing | Ball bearing |

| Gears | all Metal |

| Weight | 19 g / 0.67 oz |

| Voltage | 4.8 / 6.0 Volts |

| Torque | 3.0 kgcm / 42 oz.in |

| Speed | 0.15 sec. 60º |

| Deflection | 2 x 45º |

The servo came with

- Mounting frame and retaining screws

- Wing fairings

- Servo arms

- VMS connector and extension lead.

Case

The 10mm width has been achieved by partially exposing the motor and gearbox through windows in the case (see photo right). The windows are covered with adhesive tape to prevent dirt getting inside.

One nice point, the pot, amp and motor are all easily accessible for servicing/replacement.

Gears

Four brass gears provide the drive. According to the manufacturer, omitting a fifth gear reduces friction and inertia losses. Note steel limit pin on output shaft.

Four brass gears provide the drive. According to the manufacturer, omitting a fifth gear reduces friction and inertia losses. Note steel limit pin on output shaft.

The output shaft is supported by a substantial ball bearing.

VMS Connectors

The VMS (Volz Microconnector System) is a tiny plug/socket system. A miniature socket terminates the very short (2") stub lead from the servo. An adapter lead plugs into the socket and terminates in a servo plug to suit your system. These are available in various lengths and with various types of plug.

I like the VMS system as it allows servos to be removed quickly in the field. The sockets are 7mm x 3mm, small enough to be pulled through the aileron cable channel in my Eliminator pylon racer. If this is unsuitable for you application, you can chop off the VMS connectors and solder up your own cable.

Installation

There are no mounting lugs. The servo fits in a plastic frame and is secured using either moulded-in snap lugs or screws (or both).

There are no mounting lugs. The servo fits in a plastic frame and is secured using either moulded-in snap lugs or screws (or both).

The frame is then secured to two pieces of wood which are in turn glued into the wing. To remove the servo, you unclip (or unscrew) it from the frame.

The frame needs to bend slightly to accomodate the snap lugs. If this is not possible, two of the snap lugs can be filed off the side of the servo and the servo secured to the frame using supplied 2mm grub screws.

[15/5/2000] In response to demand Michael Volz is modifying the design of the frame and CNC wooden mounts will be available for easier installation.

Adding a Base

The servo is actually too slim to fix directly to in the top wing surface in the Ellipse I am building. I fixed the servo and support strips to a 3mm ply base which is then glued directly to the skin. See photo below.

Clevis movement

If you are using the inner hole of the servo arm, you will need to grind some material from the top of the frame to allow free movement of the clevis (You can see this mod in the right hand servo in the photo).

Other points

- The servo's is quite tall at 49mm - bear this in mind for foam wing installations.

- Spare grub screws are not provided so you may want to make up your own from suitable screws and a cutting wheel on your mini drill.

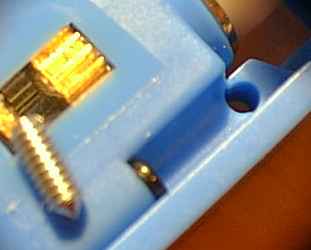

Photo shows the servo in its frame, with grub screw for locking the servo in the frame. The screw goes into the hole towards the top right. The sides of the hole are half in the servo and half in the frame.

Photo shows the servo in its frame, with grub screw for locking the servo in the frame. The screw goes into the hole towards the top right. The sides of the hole are half in the servo and half in the frame.

Performance

A simple rig using a Y-lead was set up to compare performance with some other servos I have at hand. The Wingmaxx is a lot faster than the JR 341 and MPX Super FL-BB and a little faster than the Hitec HS80. Torque under load was greatest with the Wingmaxx so all in all the Wingmaxx is the most powerful of the bunch as well as the slimmest.

Another major point in favour is that all this performance is provided by a standard 4-cell battery pack - I would say that 5 cells are unecessary for 95% of applications including F3F. I've also heard that the amps are happier on 4 cells. If more torque is required then the new HP version should suffice, but there again I've used the standard ones as flap servos with no problems.

The gear train has negligible mechanical backlash, but the straight-cut metal gears are quite noisy.

Verdict

This is more than just a radical servo - the speed and power are on just four cells are excellent. They are well suited to demanding applications such as F3B and F3F soarers.

The case configuration is unusual and I have to say that the jury is still out in this respect.

Links

- Web site : http://www.volz-servos.com/

- WingMaxx Instructions

Postscript [15 May 2000]

I've been using several WingMaxxes for almost two seasons. Planes include a 60" pylon racer, and in two F3F machines. The servos drive ailerons only in the pylon racer, and ailerons and flaps in the F3F machines.

I've had just one tooth breakage as a result of a high speed mid-air. Some slop has developed in the older servos, however this is not uncommon with small metal geared servos.

[Updated 17 June /2000]

CNC mounts are available now for moulded wings. See review of the CNC Mounts.